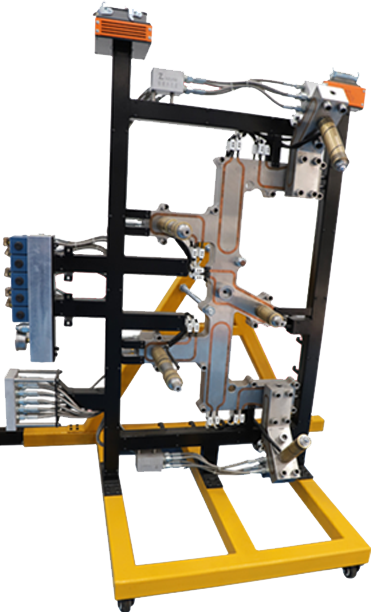

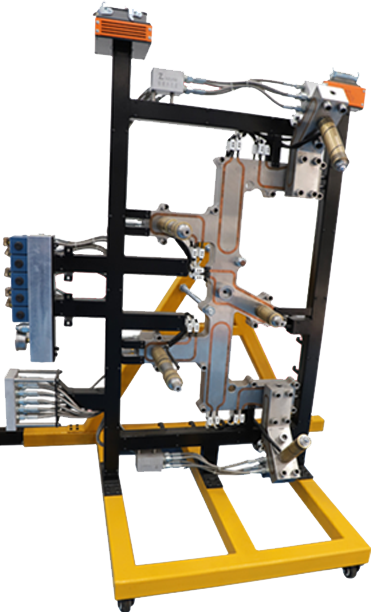

》Integrated hot runner valve gate sequence control

Plug and play, convenient installation, no leakage.

Advantage 1: integrated pre-installation design of hot runner system, simplified processing requirements,

all kinds of lines adopt track layout, compact and safe structure.

Advantage 2: the accessories have been installed on the manifold, and the system is fully tested before

ship from the factory, effectively eliminating the leakage problem of the hot runner system.

Advantage 3: can configure the cylinder system and oil cylinder system, high quality requirements to

ensure stable quality.Equipped with sequence controller, no weld line.

》Injection molding material: PP, ABS, PC+ABS, PC, PMMA, etc

Injection way: integrated valve gate, integrated open gate

Customers: GM, BYD, Huaxiang, Tianhe, Junyi, etc

Zhenxiong hot runner advantages:

1. plug and play integrated system anti-leakage project, professional automobile hot runner system;

2). the mold installation is simple and convenient, which is not limited in site by the level of installation

personnel;

3). the wire and air circuit have been connected and tested before leaving the factory.No leakage and

thread pressing;Long-term injection molding production is stable, the hot runner system is designed

according to the service life of 1 million molds.

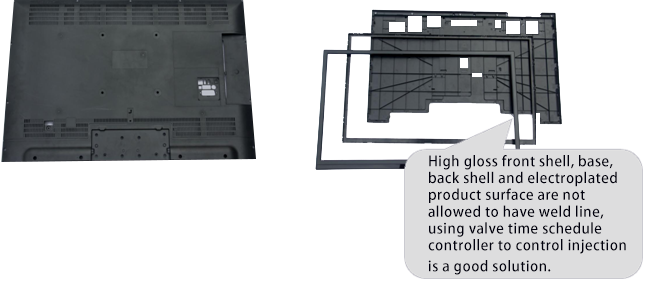

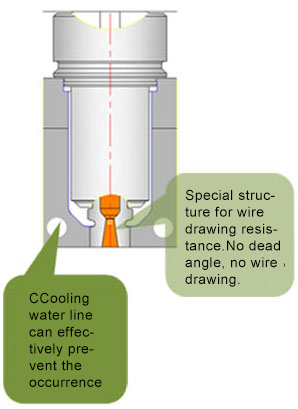

◆The most perfect gate mark

◆The lowest shear flow and the best smooth flow

◆The fastest color changing effects.

◆To provide special shaped gate and nozzle types for PMMA and PC material.

◆To provide the best gate location which can prevent the products’ surface generating streaks.

◆The perfect gate marks make the product surfacemore beautiful.

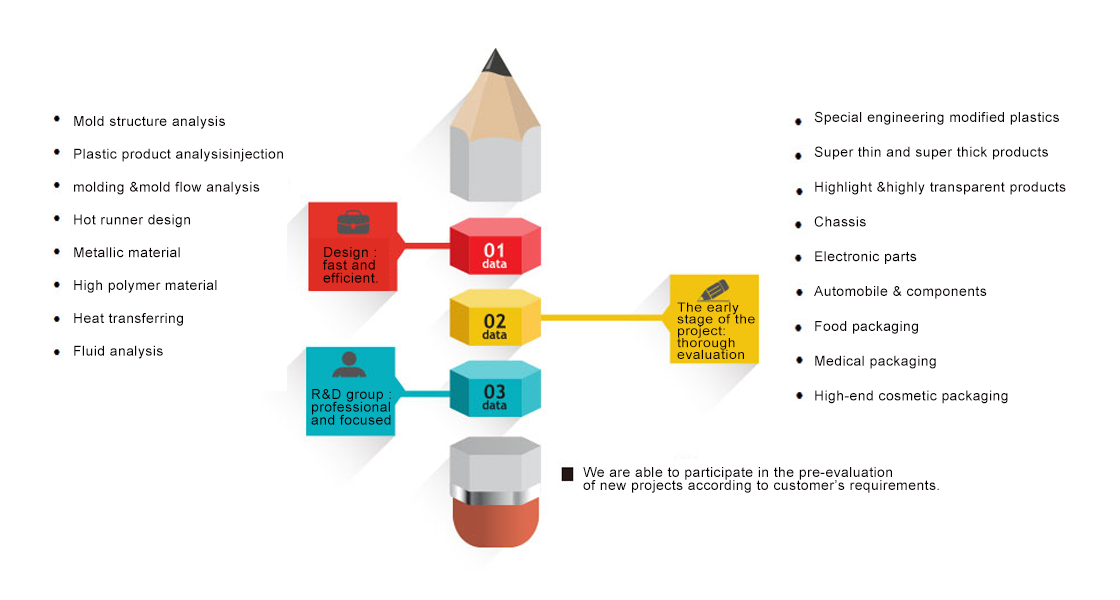

》Zhenxiong provides integrated solutions for customers:

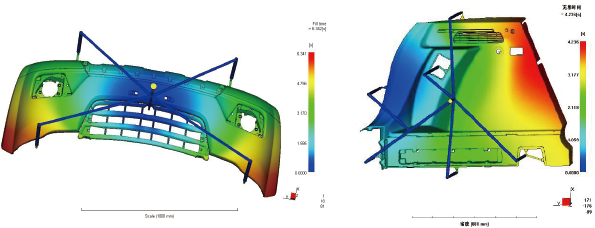

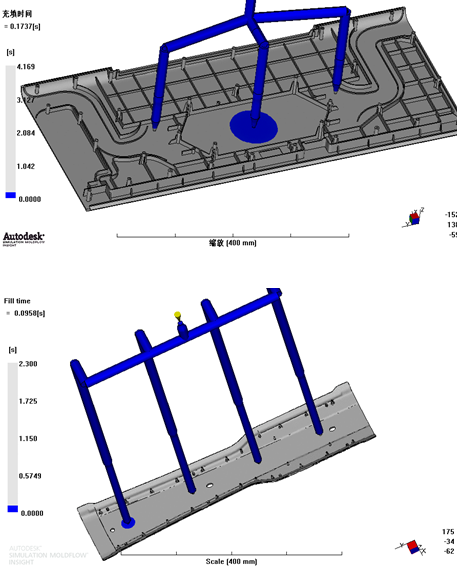

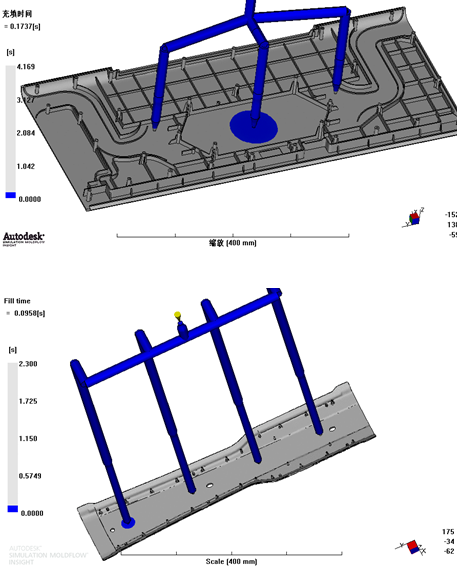

Mold structure analysis + plastic product analysis + injection molding and mold flow analysis +

hot runner design metal materials + polymer materials + heat conduction + fluid analysis

Zhenxiong can provide solutions according to customer requirements, including:

◆2D design drawing

◆3D design drawing (after 2D confirmation)

◆Mold flow analysis report

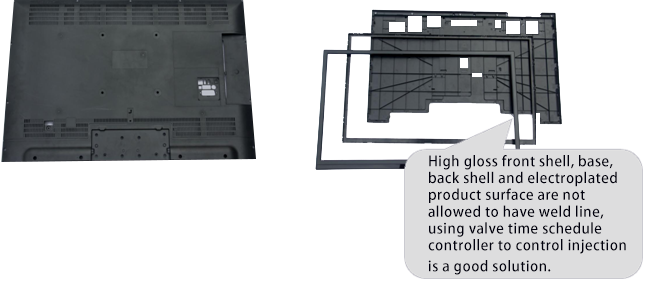

》Product surface weld line

valve sequential control injection can eliminate the product surface weld line.

Product standard

1.Zhenxiong adopts integrated time schedule controller with two working modes, diverse signal types and accuracy of 0.01s

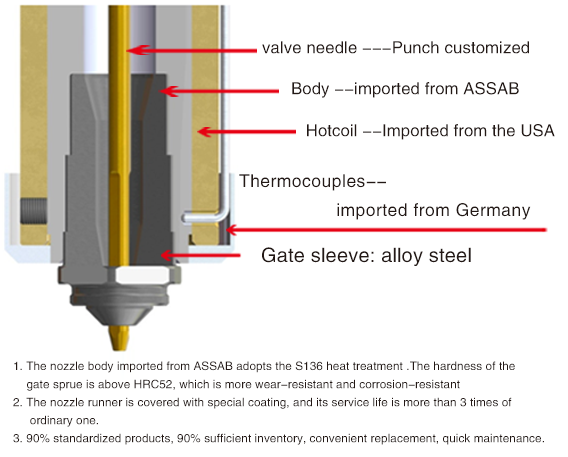

The material import

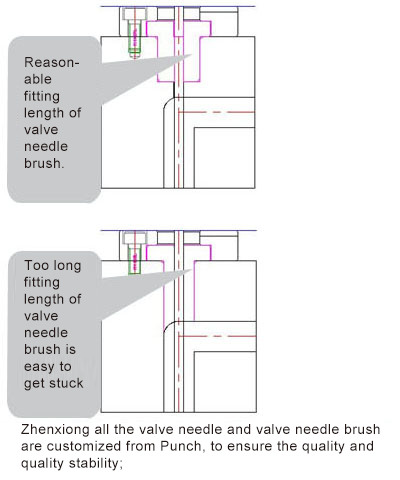

2.The valve guide bushing and valve needle are custom made by Punch. The sealing element is imported from Switzerland, high temperature resistance,

oil resistance, stable quality.

3.Technology standard

3. The solenoid valve is imported from South Korea YPC, with stable quality, sensitive response, reliable quality and durability.

The sequence of valve sequence injection can eliminate the weld line on the surface

of the product.The sequence of 4-point valve in this product can control the glue injection ,

with G1 normally open, G2 delay of 0.9s, G3 delay of 1.32s, and G4 delay of 1.86s

The sequence of valve injection can eliminate the wield line on the surface of the

product.The sequence of 3-point valve in thisproduct can control the injection .

The G1 and G3nozzles will be opened when the G2 hot nozzles are filled to 1.6s.

Automobile mold injection conditions:

Automobile mold injection conditions: Key points of product injection molding:

Key points of product injection molding:

Key points of product injection molding:

Key points of product injection molding: