MobilePhone hot runner

MobilePhone hot runner

Front and rear shell of mobile phone injection conditions:

High mold temperature, high molding temperature, thin wall, many colors,

high speed and high pressure injection

Difficulties of product molding:

Difficulties of product molding:

1) white products are prone to yellowing.

2) gate drawing.

Injection conditions of mobile phone front and rear shell :

High mold temperature, high molding temperature, thin wall, many colors,

high speed and high pressure injection

》The internal temperature error of Zhenxiong nozzle shall

not exceed 5 degrees.

Zhenxiong hot runner injection molding the metal frame of mobile phone

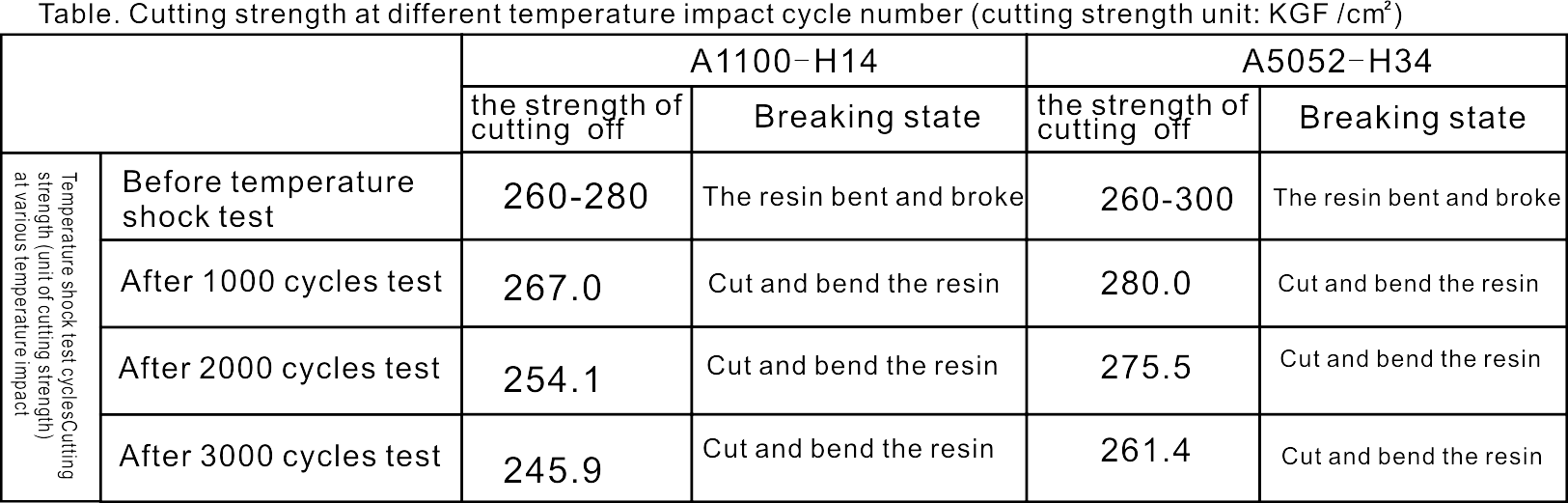

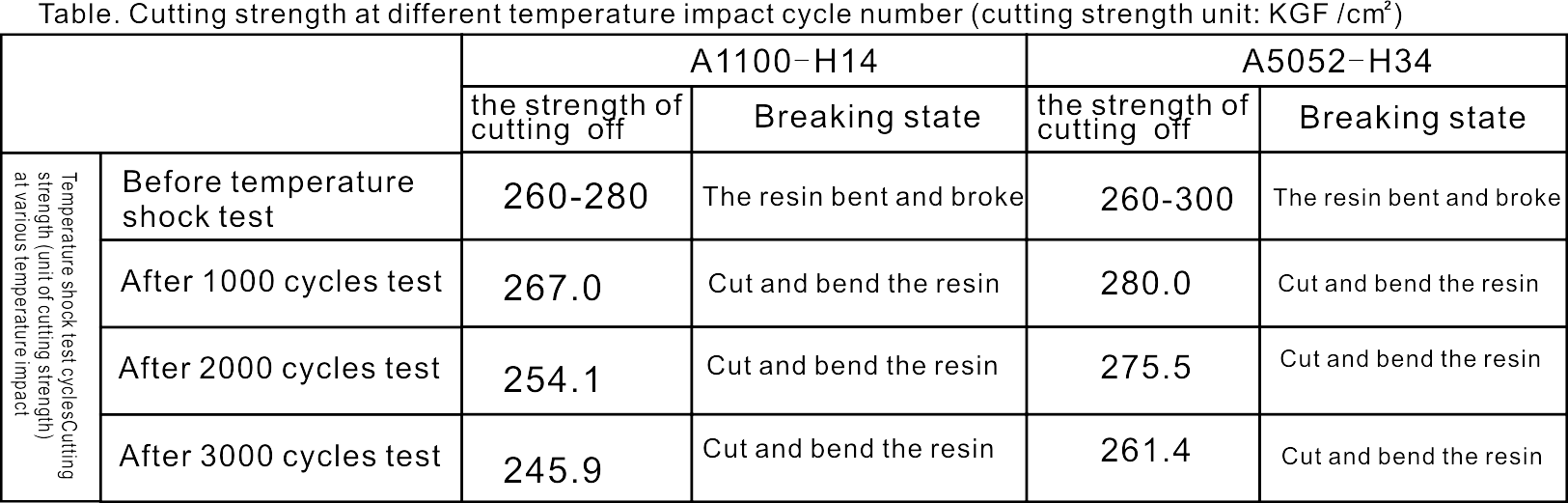

Results of temperature shock cycle test

3000 cycle cold and heat shock is the corresponding specification of engine

room of north American automobile manufacturers for 10 years.

It has been proved that the products of zhenxiong injection molding fully

meet the test standards.

》Injection molding white fireproof material, no yellow and no

drawing, stable quality

◆ Injection molding materials: PC, PC+ABS

◆ Injection method:tip ,open gate

◆ Customers: Samsung, Huawei, BBK, Xiaomi, Lenovo, etc

◆ Advantages of Zhenxiong hot runner

★ white fireproof material, no yellowing, no drawing, high-speed high-pressure

injection, no leakage, stable quality.

★ the delivery date can be delivered within 7 days at the soonest.

★ valve system quality is more stable, no needle stuck, no leakage .The hot runner

system is designed according to the service life of 2 million molds, and the

injection molding production is stable.

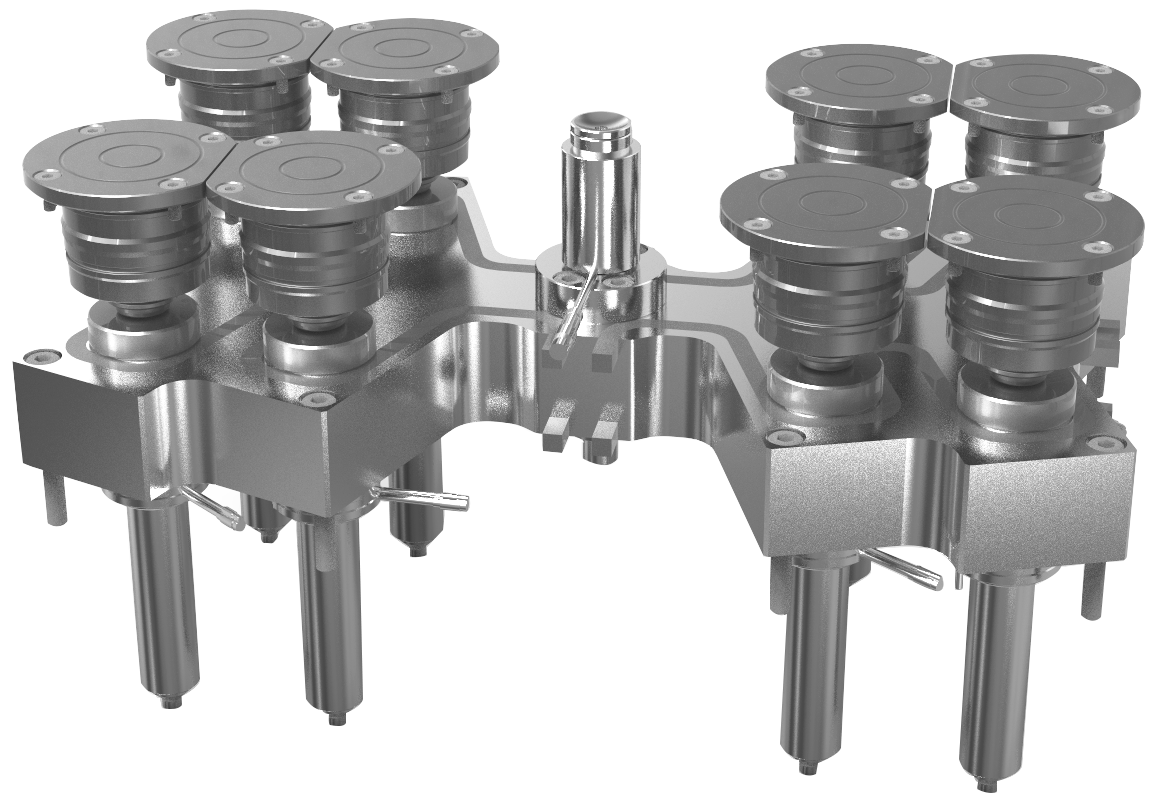

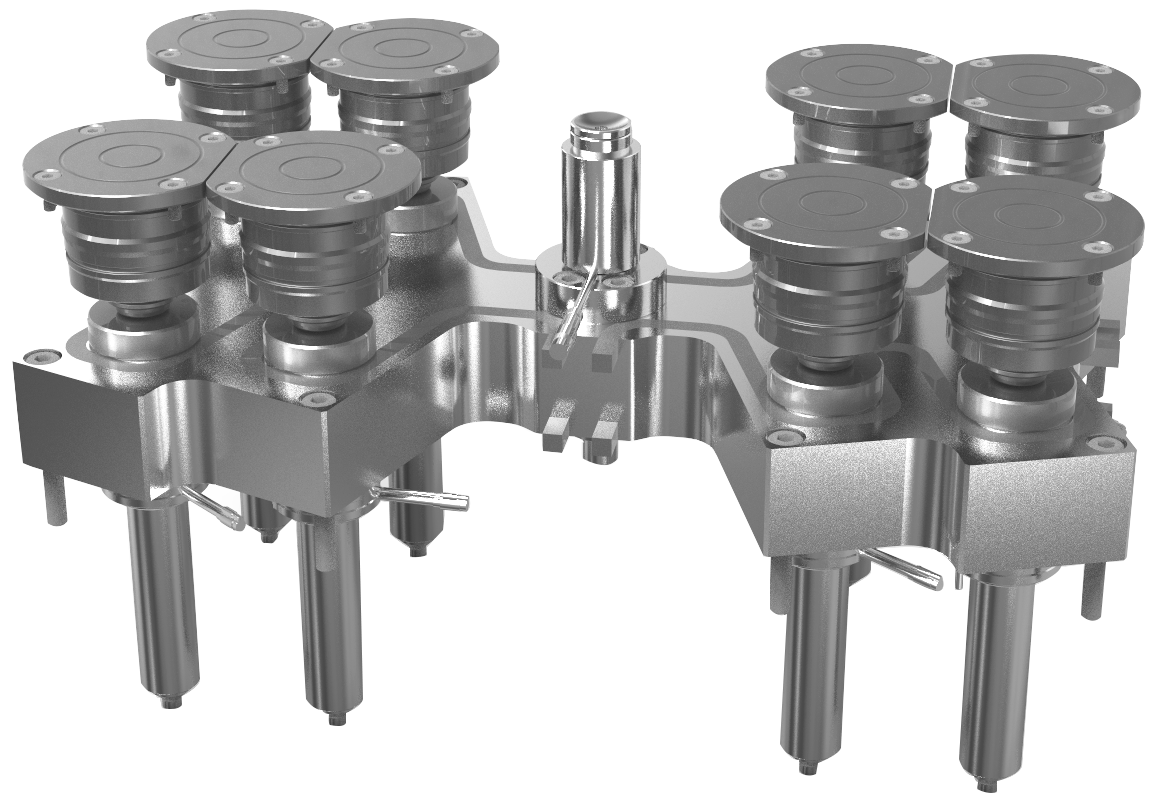

》The application of mobile phone metal frame .

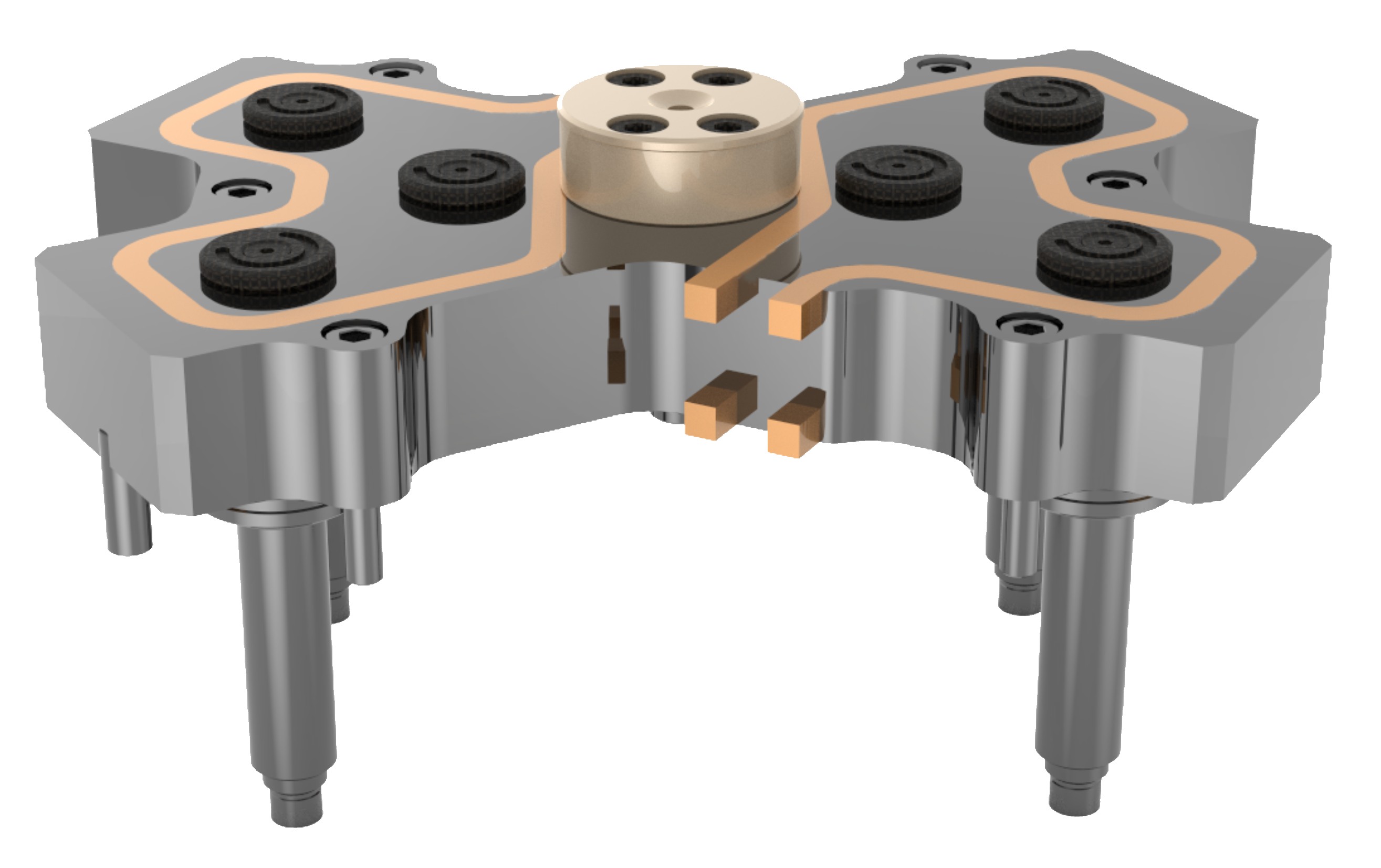

◆ Hot half mold system, easily disassembly, easily maintenance

◆ Injection materials: PPS+20~40%GF, PBT+20~40%GF

◆ Injection method: valve nozzle

◆ Customers: Huawei, Xiaomi, Samsung, Lenovo, etc.

◆ The advantages of Zhenxiong hot runner :

★ can provide the hot half mold system according to customer requirements,

which is applicable to multiple sets of molds, easy to disassemble and

assemble, and easy to maintain.

★ add high glass fiber, stable valve system quality, no stuck, no leakage.The hot

runner system is designed according to the service life of 1 million molds, and

the injection molding production is stable.

★ the hot half mold delivery period can be delivered within 10 days at the soonest.

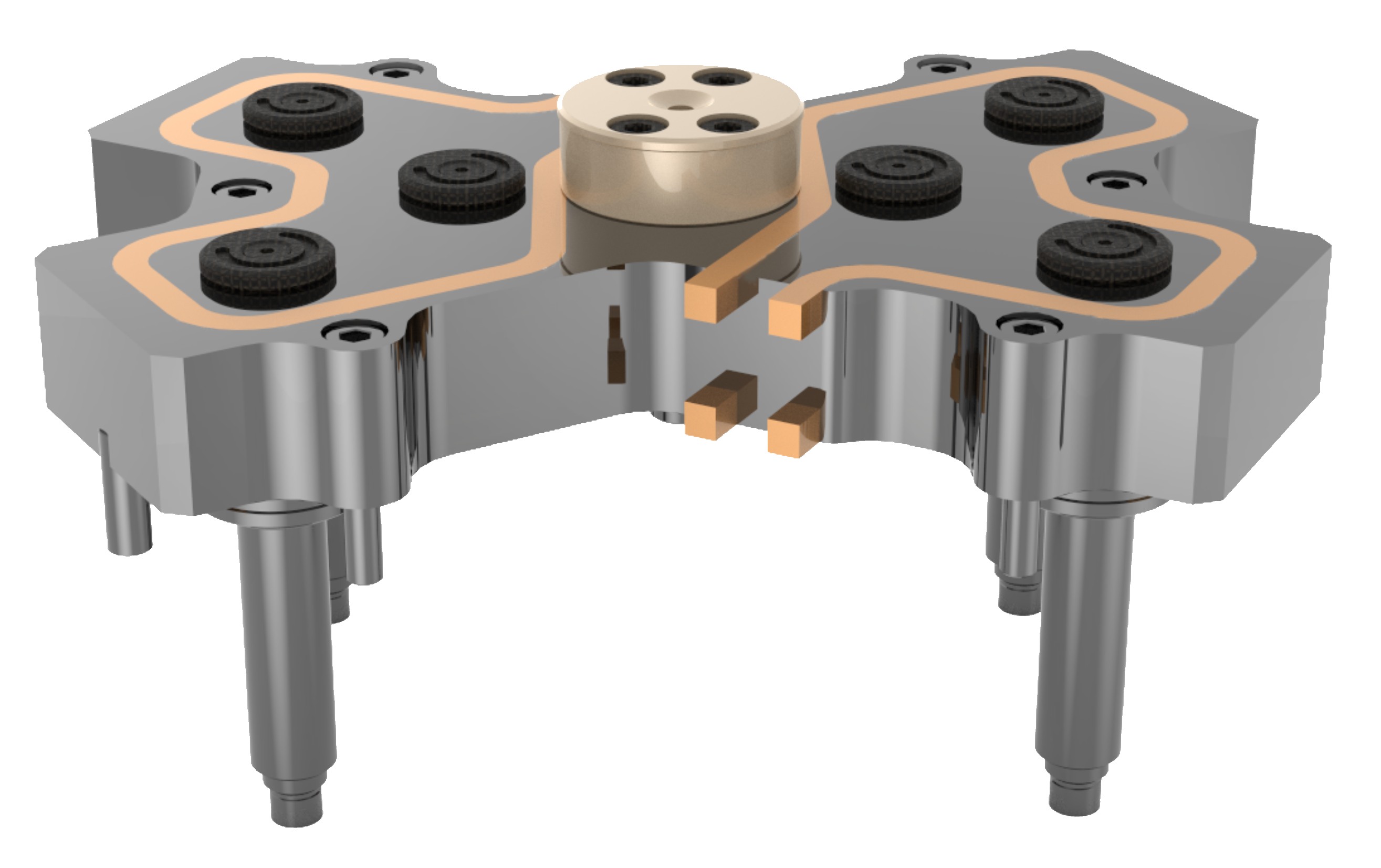

》Application of Mobile phone charger shell PC white square nozzle system

◆ Injection molding material: PC

◆ Injection method: valve nozzle or tip nozzle

◆ Customers: Samsung, Huawei, Xiaomi, etc

◆ Advantages of Zhenxiong hot runner :

★ special nozzle for charger socket, complete hot runner system without gate,

nozzle cavity is 10mm.

★ PC white without yellowing and wire-drawing, beautiful gate and stable

quality;

★ multi-cavity hot runner has good balance and stable product size.

the hot runner system is designed according to the service life of

1 million molds with stable molding production .

》Front and rear shell of mobile phone injection conditions:

◆ High mold temperature, high molding temperature, thin wall, many colors,

◆ High mold temperature, high molding temperature, thin wall, many colors,

high speed and high pressure injection Difficulties of product molding:

◆ white products are prone to yellowing.

◆ gate drawing.

★ Injection conditions of mobile phone front and rear shell :

★ High mold temperature, high molding temperature, thin wall, many colors,

high speed and high pressure injection

》Reasons for system leakage.

■ Zhenxiong manifold is inserts and polished by the runner polishing machine

Along with Hot fit application (interference fit) without leakage .

Leakage of nozzle sealing

■ Zhenxiong has strict testing training and requirements for all the installation

personnel. Only when all the dimensions are processed accurately according

to the drawings can they be installed to ensure no leakage.

Nozzle and manifold matching surface leakage.

■ zhenxiong design has avoided possible machining errors, as shown in the

right figure

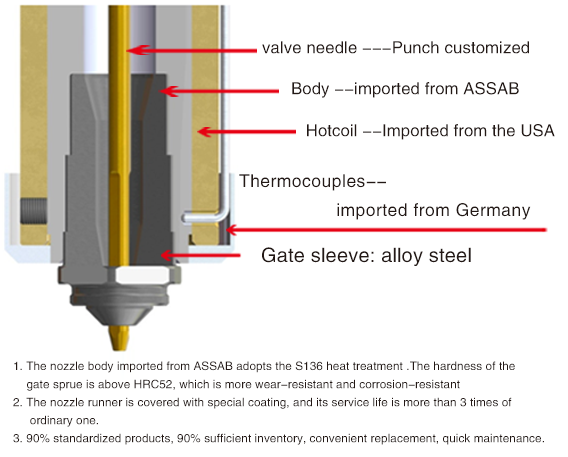

■ Zhenxiong focuses on engineering materials and high glass fiber products

Imported steel, specially treated, more wear - resistant and corrosion - resistant

■ Zhenxiong nozzles are made of imported steel with special treatment,

effectively ensuring the life of products. The quality of hot runner products is

designed with 10 years' service life, and the design life of products with fiber

added within 15% is designed with 2 million times of mold.

》Zhenxiong focuses on engineering material and high fiber products

Imported steel, specially treated, more wear - resistant and corrosion -resistant

Zhenxiong nozzles are made of imported steel with special treatment, effectively ensuring the life of products. The quality of hot runner

products is designed with 10 years' service life, and the design life of products with fiber added within 15% is designed with 2 million times of mold.

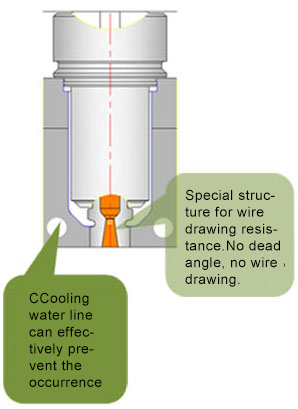

》Reasons for products yellowing ,black coating.

■ Dead angle existed in nozzle outlet .

Zhenxiong has professional MTO patent for molding transparent/color changing products nozzle.This type of nozzle

has no dead angle, fast color change and small pressure loss.

■ There is a dead angle at the corner of the manifold. The plug at the

junction angle of the runner adopts smooth transition, and the special

position adopts mosaic structure to ensure the junction angle is smooth.

■ The plastic material stays in the runner too long.

See attached page for detailed calculation of plastic injection volume and

residence time

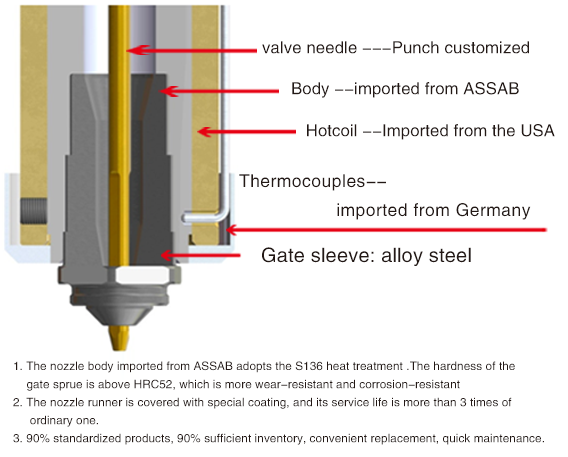

》Nozzle temperature difference accuracy

The internal temperature error of zhenxiong nozzle is no more than 10 degrees.

product standard

1. 90% of the products are standardized and 90% are in

sufficient inventory.

Standardized production ensures the consistency of quality.

2. Material import

Nozzles are made of ASSAB imported materials, and the

processing technology is strictly controlled to ensure the

interchangeability of

nozzles effectively.

3 .Process standard

The heating coil winding method has been tested strictly, the winding

process is standardized, and high quality is required to ensure stable

quality.

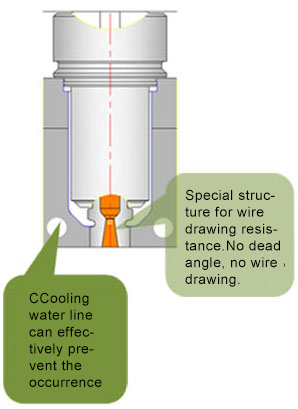

》Causes of wire drawing drooling of gate.

There is no reasonable cooling at the tip of the nozzle.

Reasonable cooling water line should be designed near the nozzle gate to increase

cooling Water line can avoid problems such as wire drawing and drooling caused by

heat accumulation at the gate

The nozzle selection is unreasonable

Zhenxiong nozzle is a special structure without nozzle core, without drawing and

drooling. Valve type nozzle is recommended for drawing caused by extreme injection

molding condition .

The temperature of nozzle is not stable and the long-term production stability is poor.

Zhenxiong heating accessories are imported , see the attached page

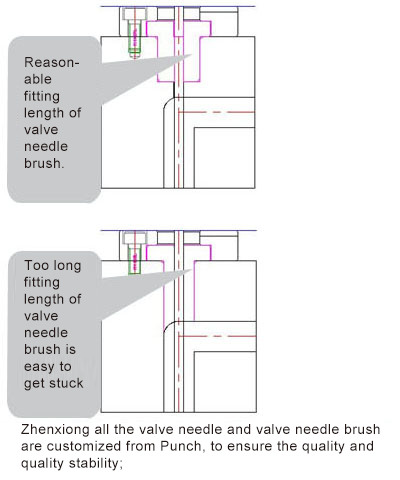

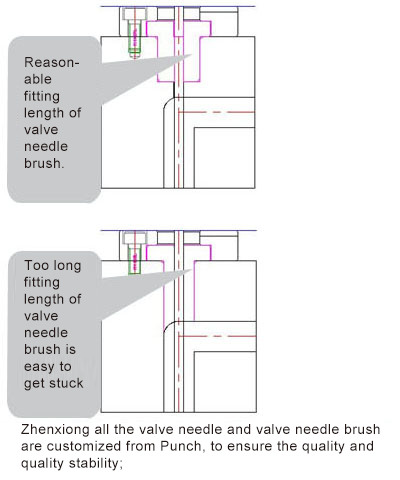

》Causes for valve needle stuck:

1. The valve needle is too long with the needle brush.

The matching length between the guide brush and the valve needle of zhenxiong

is shorter than other companies,which get less needle stuck.

2. Improper fitting tolerance between valve needle and needle brushing.

The matching tolerance between the guide brush and the valve needle of Zhenxiong

is customized according to the fiber adding material, and it has been tested and verified

repeatedly to ensure no leakage and needle stuck.

3. Processing error leads to unqualified or unstable quality.

.

MobilePhone hot runner

MobilePhone hot runner Difficulties of product molding:

Difficulties of product molding: